branill hardness tester|brinell hardness testing charts : ODM The typical test uses a 10 mm (0.39 in) diameter steel ball as an indenter with a 3,000 kgf (29.42 kN; 6,614 lbf) force. For softer materials, a smaller force is used; for . See more Resultado da 2 horas atrás · Com canções de Jorge Ben e Tim Maia, shows na cidade maravilhosa apostaram em clássicos do samba, MPB e pagode em 2023. .

{plog:ftitle_list}

web2 de fev. de 2023 · Curtiu? Siga o PORTAL DO ZACARIAS no Facebook, Twitter e no Instagram. Entre no nosso Grupo de WhatApp e Telegram . DEFESA. O advogado de defesa, Eugênio Malavasi, informou que até o .

Proposed by Swedish engineer Johan August Brinell in 1900, it was the first widely used and standardised hardness test in engineering and metallurgy. The large size of indentation and possible damage to test-piece limits its usefulness. However, it also had the useful feature that the hardness value divided by two . See moreThe Brinell scale /brəˈnɛl/ characterizes the indentation hardness of materials through the scale of penetration of an indenter, loaded on a material test-piece. It is . See moreThe typical test uses a 10 mm (0.39 in) diameter steel ball as an indenter with a 3,000 kgf (29.42 kN; 6,614 lbf) force. For softer materials, a smaller force is used; for . See moreWhen quoting a Brinell hardness number (BHN or more commonly HB), the conditions of the test used to obtain the number must be specified. The standard format for specifying tests can be seen in the example "HBW 10/3000". "HBW" means that a . See more

• International (ISO) and European (CEN) Standard• US standard (ASTM International) See more• Brinelling• Hardness comparison• Knoop hardness test• Leeb rebound hardness test See more• Brinell Hardness Test – Methods, advantages, disadvantages, applications• Video on the Brinell hardness test on YouTube• Rockwell to Brinell conversion chart (Brinell, Rockwell A,B,C) See more

The Brinell hardness test method as used to determine Brinell hardness, is defined in ASTM E10. Most commonly it is used to test materials that have a structure that is too coarse or that have a surface that is too rough to be tested .A basic Brinell hardness tester with semi-automatic operation. NB3010 is a cost-effective Brinell tester using deadweights with a pneumatic load system to apply and remove the loads. .Learn how to use Brinell hardness test units and testing machines to quickly and accurately assess large samples with a coarse or inhomogeneous grain structure – with knowledge and insight from Struers, the world’s leading .

lee brinell hardness tester chart

Choose from our selection of brinell hardness testers, including Rockwell hardness testing file sets, Durometer hardness testers, and more. In stock and ready to ship.According to ISO 6506, the spherical indenter made of hard metal (tungsten carbide) is pressed into a specimen (workpiece) with a defined test load (between 1 kgf and 3000 kgf) to determine the Brinell hardness (HBW).Brinell hardness testing is a commonly used method for determining the hardness of metals and alloys. The Brinell hardness test formula. When measuring hardness using the Brinell .

The Brinell hardness test is a widely recognized method for determining the hardness of various materials. It involves applying a constant load or force, typically ranging from 187.5 to 3000Kgf, for a specified time period, usually .The Wilson BH3000 Brinell Hardness Tester stands as a robust Brinell hardness tester, boasting a wide range from 62.5 kgf to 3000 kgf. Blends high rigidity and closed-loop load cell technology to ensure precise and secure load .

how hard is the human resource test

The Brinell hardness test is defined in ASTM E10 is used to calculate Brinell hardness of the metal. It is used on the metal having a rough surface and harsh texture. The Brinell hardness test is used to measure the .The Lead Hardness Tester Standard Model is one of the easiest to use lead testers on the market. Use for testing cast bullets and ingots. Features a large and easy to read dial indicator. A conversion chart for SAECO and Brinnell is included. Unit is all steel, weighs approximately 5 lbs, with a black oxide finish. Testing an ingot. Install the dial indicator on the holding rod and .The Brinell hardness Tester features a fully automatic test cycle, load application, holding, unloading, is performed fully automatically. This greatly improves reproducibility of test results since operator influence is eliminated.Ernst, Brinell Shear Pin Hardness Tester . ERNST STE-B. The ERNST STE-B calibrated pin system replaces the impact bar system giving a greater versatility and high accuracy. The indentations can be made very quickly even by an unskilled operator. The indentation can be read immediately, or at a later time by an inspector. .

Brinell Hardness Testers Manual: 9000N Series Hardness Testers Manual in English: 7000 Series Hardness Testers : Manual in English: NB3010 Seres Hardness Testers Manual in English: KB Series Hardness Testers Manual in English: Pin Brinell Hardness Tester .Brinell Hardness Test Blocks DIN EN ISO 6506-3, ASTM E10. Order Data. Knoop Hardness Test Blocks DIN EN ISO 4545-3, ASTM E92. Order Data. Rockwell Hardness Test Blocks DIN EN ISO 6508-3, ASTM E18. Order Data. Vickers Hardness Test Blocks DIN EN ISO 6507-3, ASTM E92. Order Data.BRINELL HARDNESS TESTER MODEL NB-3010 Including Appendix for Retrofit of HB3000 to NB3010 OPERATING INSTRUCTIONS V 1.0 Issue 06/2016. Contents 1. APPLICATION INFORMATION 1 . Brinell Test Block, HB30 10mm ball indenter with carbide ball and cert. Brinell Chart Certificate of calibration for tester

The Newage Pin Brinell is the de-facto standard for economical Brinell hardness measurement. This simple-to-use and inexpensive tester can be used across the entire Brinell range (HB100 to HB700).

LECO offers a wide selection of hardness testing systems to match any application or budget. Choose from manual and automatic model configurations for Microindentation, Macro-Vickers, Multi-Vickers, Brinell or Rockwell type testing. Our automatic hardness systems, designed to maximize your productivity, increase usability, simplify reporting, and streamline analysis times.Brinell hardness testing is widely used for large parts like engine castings and piping, where high loads and large indents offer precise hardness determination. The method’s versatility is constrained by the indenter ball’s deformation with harder materials, and the importance of load and ball diameter ratios for accurate results. . Brinell hardness testing involves pressing an indenter ball into the surface of a metal under a load and measuring the diameter of the indentation. Rockwell hardness testing measures the additional depth of a heavy load indenter beyond the depth of a previously applied light load. Both tests provide standardized hardness values and have . One of those articles is a comparative test of most of the common lead hardness testers. Participants did blind tests of sample bullets all cast in the same lot. I was one of the LBT testers using a 30 year old tool that agreed well with the standard results. The standard result was from a calibrated commercial brinell test machine in a metals lab.

The 2 steps for the principle of the Brinell test method. The general principle of the Brinell indentation hardness test consists of two steps: Step 1 – The indenter is brought into contact with the test specimen in a direction perpendicular to the surface, and the test force is applied (Apply the test force within 1 to 8 s). The test force is held for a specified dwell time and then .Testing coarse material with the Brinell hardness testing method. The Brinell hardness tester uses the oldest method of hardness testing commonly used today. It was invented in Sweden by Dr. Johan August Brinell in 1900. This test is often used to determine the hardness of castings and forgings whose grain structure is too coarse for accurate Rockwell or Vickers testing.

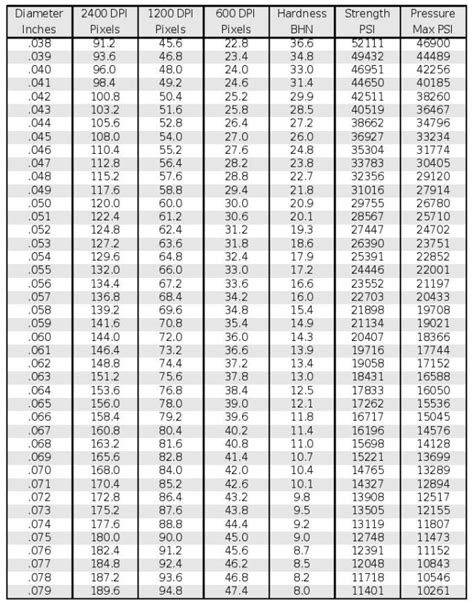

There are two types of Leeb hardness testers such as bench (stationary, classical) as well as portable (mobile, electronic). Bench hardness tester– This bench hardness tester is a traditional type used to determine the hardness .Brinell Hardness Testing Equation. Table A Brinell Hardness to Rockwell Hardness Conversion Table . Brinell Hardness: Rockwell Hardness: Tensile Strength (Approximate) Psi: Tungsten Carbide Ball 3000 KG: A Scale 60KG: B Scale 100KG: C Scale 150KG-85.6-68.0--85.3-67.5--85.0-67.0-767: 84.7-66.4-757: 84.4-65.9-745: 84.1-65.3-733: 83.8-64.7-722: 83 .

Direct Reading Brinell Hardness Testing System Series 9000N Version 8.1 OperatiOn Manual 12. Contents i. Routine Inspection and Emergency Return Checklist. . . . . . . . . vii . L ke the Rockwell hardness test method, th s depth measurement s calculated based on the d fference n penetrat on depth between a preload and a major load pos t on .

King Portable Brinell Hardness Testers are the most reliable, easy to use and affordable portable Brinell testers that are certified and calibrated per ASTM E-10 standards and the ONLY portable Brinell testers on the market that are accurate to within 1% with traceability to NIST.

one tester, all rockwell scales, regular & superficial, and light load brinell test instantly available with the touch of a finger. In addition to all Standard Rockwell Test Loads, the LC-200R Series allowUser Selection of Minor/ Major Load Combination(anywhere between 3 and 200 kgf) allowing Creation of Customized Rockwell Type Test - Ideal .Newage offers optical solutions for your hardness testing include the popular B.O.S.S.™ Brinell Optical Scanning System, HiLight® optical scope and pocket optical scope.The material testing machine division of Fuel Instruments and Engineers Pvt. Ltd. (FIE Group) is a leading manufacturer of material testing machines. Worldwide, we offer testing machine solutions across a wide range of applications.

brinell hardness testing machine diagram

The Wilson BH3000 Brinell Hardness Tester stands as a robust Brinell hardness tester, boasting a wide range from 62.5 kgf to 3000 kgf. Crafted with rugged construction for resilience in challenging environments, this reliable hardness tester blends high rigidity and closed-loop load cell technology to ensure precise and secure load applications.

Model No. PHT-1900 Features. State of the art, digital portable hardness tester is designed to test the hardness of large hard metal parts. Clean crisp display shows the incredible functions that can only be found on this new portable hardness tester such as auto-probe detection, auto direction detector, single and multi-point calibration make the new 1900 the most versatile .Brinell indentation Optical measuring system adopts advanced machine vision technology, through the digital microscope to photograph the indentation left by the specimen after the test force is loaded by the Brinell hardness tester, which can measure the Brinell hardness value of the specimen tested by different indenters of 10mm, 5mm, 2.5mm, 1mm.Telebrineller Brinell Portable Hardness Tester. Teleweld Telebrineller Bars. Teleweld Telebrineller Bars Test Bars for Telebrineller & Halteman Testers. Telebrineller Bars. Available in many BHN values. Certified accuracy is +/- 3% of labeled hardness. 9/16” square, 6” in length. BHN Values Table.5 Bars of Selected Hardness. Telebrineller test bars are included in your kit (your selected hardness). These are the core of the system and calibrated to a uniform hardness of +- 2% of the labeled BHN. Hardness of the bars is measured by accurate equipment certified traceable to the National Standards Institute.

how hard is the hvac epa test

The DuraVision universal hardness testers for standard load ranges of 0.3-250 kgf or 3-3,000 kgf can be used for Vickers, Knoop, Brinell, and Rockwell tests, as well as for carbon and plastics testing.All methods are covered by the ISO 6506, ISO 6507, ISO 45452, ASTM E384, ASTM E92, ASTM E10, ISO 6508, ASTM E18, DIN 51917 and ISO 2039 standards. The DuraVision .

how hard is the hvacr test

Resultado da Título Título ou resumo errado ou episódio fora de ordem Vídeo Desfocado, cortado ou parece estranho de alguma forma Som Difícil de ouvir, não compatível com o vídeo ou ausente em algumas partes Legenda Ausente, difícil de ler, erros ortográficos Problema de buffer ou conexão Fica só .

branill hardness tester|brinell hardness testing charts